AD 86-15-07 Larger Engine Modification

July 24, 1986

This AD applies to the 150, 150A, 150B, and 150C that have been modified with an engine larger than the Continental 0-200-A.

To ensure operation of the airplane is within the approved center of gravity (CG) limits the modified airplane must be weighed to determine the Empty Weight and CG. Then calculate the weight and CG when an average pilot is added. If the CG falls too far forward, ballast must be added where the battery was because it was probably moved when you put the bigger engine in.

If the weight, including the ballast, exceeds 1142 pounds, a placard must be installed limiting the airplane to single pilot operation. If the weight exceeds 1195, something has to come out to reduce the weight.

86-15-07 CESSNA: Amendment 39-5358. Applies to the following Models and Serial Numbers of airplanes certificated in any category which have been modified by the installation of an engine larger in size and/or horsepower than the Continental 0-200-A:

| MODELS | SERIAL NUMBERS |

| 150 | 17001 thru 17999, 59001 thru 59018 |

| 150A | 15059019 thru 15059350 |

| 150B | 15059351 thru 15059700 |

| 150C | 15059701 thru 15060087 |

Compliance: Required as indicated, unless already accomplished.

To assure operation of the airplane within the approved center of gravity (cg) limits, accomplish the following:

(a) Within the next 25 hours time-in-service (TIS) after the effective date of this AD, accomplish the following:

(1) Weigh the airplane to determine the empty weight (W1) and calculate the cg (cg1). The airplane, as weighed, must include full oil and unusable fuel (21 lbs at fuselage station 40.0 for standard fuel tanks).

(2) Add pilot weight (170 lbs at fuselage station 39.0) to the empty weight (W1+170=W2) and calculate the cg (cg2) for this condition. If this cg is forward of fuselage station 32.2, add ballast between fuselage stations 70.69 and 76.44. (This was the location of the battery prior to the engine modification.)

(3) Determine the amount of ballast (B) required from the following equation:

(D) x (W2)

B = _________ ; where,

X

B = weight in pounds of ballast required by this AD.

D = distance in inches the empty A/C (with pilot) cg must be moved aft in order to comply with this AD (D=32.2-cg2). Obtain cg2 from paragraph (2) above.

W2 = empty weight in pounds of the airplane plus pilot determined in paragraph (2) above.

X = distance in inches from the point where the ballast is installed to the required location of the new cg (fuselage station 32.2 in this case). Using the battery box location, X = 41.36.

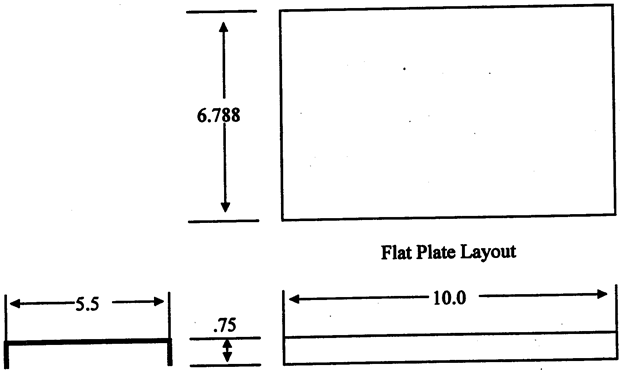

(4) Fabricate the channel detailed in Figure 1. Mount the channel between fuselage stations 70.69 and 76.44 using the existing 041328-3 brackets. Attach with MS20470- AD4 rivets through the existing holes in brackets. Install the ballast in accordance with Figure 1. If ballast exceeds 60 pounds, contact the Wichita Aircraft Certification Office at the address given in paragraph (d) below for assistance.

(5) If the empty weight, as calculated in (1) above, plus the ballast exceeds 1142 lbs, prior to further flight, fabricate and install on the instrument panel a placard with a minimum letter size of 1/8 inch which states, “WARNING: THIS AIRPLANE LIMITED TO SINGLE OCCUPANT”. If the empty weight exceeds 1195 lbs., equipment must be removed in order that this weight is not exceeded. The 1142 lbs and 1195 lbs are weight limitations established by Civil Air Regulations 3.74(b) (1) and 3.74(b) (2), respectively.

(b) Airplanes which were weighed at the time of installation of the larger engine and have an empty weight cg (including pilot, oil and unusable fuel) aft of fuselage station 32.2 are exempt from paragraphs (a)(1), (a)(2), (a)(3) and (a)(4) of this AD.

(c) Airplanes may be flown in accordance with FAR 21.197 to a location where this AD may be accomplished.

(d) An equivalent method of compliance with this AD may be used if approved by the Manager, Wichita Aircraft Certification Office, FAA, 1801 Airport Road, Room 100, Wichita, Kansas 67209; Telephone (316) 946-4400.

This amendment, 39-5358, becomes effective July 24, 1986.

| MATERIAL: | 2024-T3 |

| THICKNESS: | .040 |

| BEND RADII: | .125 |

| SCALE: | 1/2 |

| DIMENSIONS: | Inches |

| NOTE: Lead ballast can be stacked sheet stock, ingot, or bar stock. Attach sheet stock with a minimum of 4-AN4 bolts or equivalent. Attach ingots or bar stock with a minimum of 2- AN4 bolts or equivalent per piece of lead, install a large diameter washer, such as an AN 970-4 under both the bolt head and nut. Use either a locknut or a castellated nut with cotter pin |