AD 96-12-22 Oil Filter Adapter

July 31, 1996

This AD applies to all airplanes equipped with Cessna Engine Oil Filter Adapter Assemblies installed on Continental engines.

This AD requires inspecting the Cessna Engine Oil Filter Adapter assemblies (or torque putty, if installed) for oil leakage and proper installation of the adapter retaining nut and fretting of associated threads. Reports of loose or separated engine oil filter adapters on several airplanes prompted this action. The actions specified by this AD are intended to prevent loss of engine oil caused by loose or separated oil filter adapters, which, if not detected and corrected, could result in engine stoppage while in flight and loss of control of the airplane.

96-12-22 CESSNA AIRCRAFT COMPANY: Amendment 39-9665; Docket No. 93-CE-54-AD.

Applicability: Cessna Engine Oil Filter Adapters Assemblies, part numbers 0450404-(all dash numbers), 0556004-(all dash numbers), 0556010-(all dash numbers), 0756023-(all dash numbers), 0756024-(all dash numbers), 1250403-(all dash numbers), 1250417-(all dash numbers), 1250418(all dash numbers), 1250921-(all dash numbers), and 1250922-(all dash numbers), installed on, but not limited to, the following:

(1) Cessna Models 100, 200, 300, and 400 Series airplanes (all serial numbers), certificated in any category, that are equipped with at least one Teledyne Continental Motors (TCM) engine.

(2) Airplanes that have an affected full flow engine oil adapter installed by field approval, including, but not limited to, the following model or series airplanes, certificated in any category:

| Manufacturer | Series/Models |

| Rockwell/Aero Commander/Meyers | 200 Series |

| Twin Commander | Models 500A and 685 |

| Beech | 33, 35, 36, and 55 Series |

| Piper | PA46 Series |

| Navion | Rangemaster 17 Series |

| Wren | Model 460 |

| Bellanca | 260 and 300 Series |

(3) Airplanes equipped with any of the following Teledyne Continental Motors model or model series engines:

| O-200 | O-470 | IO-470 |

| TSIO-470 | O-520 | IO-520 |

| TSIO-520 | GTSIO-520 | IO-550 |

| TSIO-550 |

NOTE 1: This AD applies to each airplane identified in the preceding applicability provision, regardless of whether it has been modified, altered, or repaired in the area subject to the requirements of this AD. For airplanes that have been modified, altered, or repaired so that the performance of the requirements of this AD is affected, the owner/operator must request approval for an alternative method of compliance in accordance with paragraph (f) of this AD. The request should include an assessment of the effect of the modification, alteration, or repair on the unsafe condition addressed by this AD; and, if the unsafe condition has not been eliminated, the request should include specific proposed actions to address it.

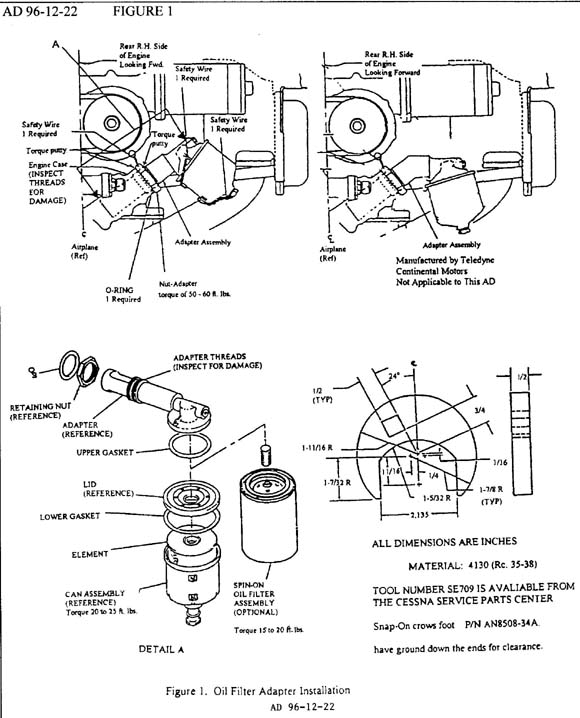

NOTE 2: This AD does not apply to engine oil filter adapter assemblies manufactured by Teledyne Continental Motors (See Figure 1 of this AD).

Compliance: Required initially as specified in both of the following, and thereafter as indicated in the body of this AD:

1. Within the next 100 hours time-in-service (TIS) after the effective date of this AD or when the engine oil filter is removed, whichever occurs first; and

2. Every time the engine oil filter is removed.

To prevent loss of engine oil caused by loose or separated oil filter adapters, which could result in engine stoppage while in flight and loss of control of the airplane, accomplish the following:

(a) For airplanes with engine oil filter adapter assemblies that do not have torque putty between the engine filter adapter assembly, nut, and oil pump housing, accomplish the following:

(1) Inspect the adapter locking nut installation for evidence of oil leakage.

(2) Check the torque of the adapter nut installation and ensure that the torque value is within the limits of 50 through 60 foot pounds.

(3) If evidence of oil leakage is found or the torque is not within the 50 through 60-foot pound limit, prior to further flight, remove the adapter and filter assembly, and:

(i) Inspect the threads of the adapter assembly and engine for signs of damaged or cracked threads; and

(ii) Replace any adapter assembly and engine oil pump housing (if necessary) that have evidence of thread damage or cracks.

(4) Apply torque putty between the engine filter adapter assembly, nut, and oil pump housing as specified in Figure 1 of this AD.

(5) Reassemble the engine oil filter assembly.

(b) For airplanes with torque putty between the engine filter adapter assembly, nut, and oil pump housing, inspect the torque putty for misalignment, evidence of oil leakage, or cracks.

(1) If any misalignment, evidence of oil leakage, or torque putty cracks are found, prior to further flight, accomplish the requirements specified in paragraph (a) of this AD, including all subparagraphs.

(2) If no misalignment, evidence of oil leakage, or torque putty cracks are found, reinspect at intervals not to exceed 100 hours TIS until the engine oil filter is removed.

(c) Replacing the engine oil filter adapter assembly does not eliminate the repetitive inspection requirement of this AD.

(d) The repetitive inspections of the torque putty as required by this AD may be performed by the owner/operator holding at least a private pilot certificate as authorized by section 43.7 of the Federal Aviation Regulations (14 CFR 43.7), and must be entered into the aircraft records showing compliance with this AD in accordance with section 43.11 of the Federal Aviation Regulations (14 CFR 43.11).

(e) Special flight permits may be issued in accordance with sections 21.197 and 21.199 of the Federal Aviation Regulations (14 CFR 21.197 and 21.199) to operate the airplane to a location where the requirements of this AD can be accomplished.

(f) An alternative method of compliance or adjustment of the initial or repetitive compliance time that provides an equivalent level of safety may be approved by the Manager, Wichita Aircraft Certification Office (ACO), 1801 Airport Road, Room 100, Mid-Continent Airport, Wichita, Kansas 67209. The request shall be forwarded through an appropriate FAA Maintenance Inspector, who may add comments and then send it to the Manager, Wichita ACO.

NOTE 3: Information concerning the existence of approved alternative methods of compliance with this AD, if any, may be obtained from the Wichita ACO.

(g) Information related to this AD may be examined at the FAA, Central Region, Office of the Assistant Chief Counsel, Room 1558, 601 E. 12th Street, Kansas City, Missouri 64106.

(h) This amendment becomes effective on July 31, 1996.